LA Hard Tech Spotlight: Senra Systems

Mission critical wire harnesses for modern hardware companies

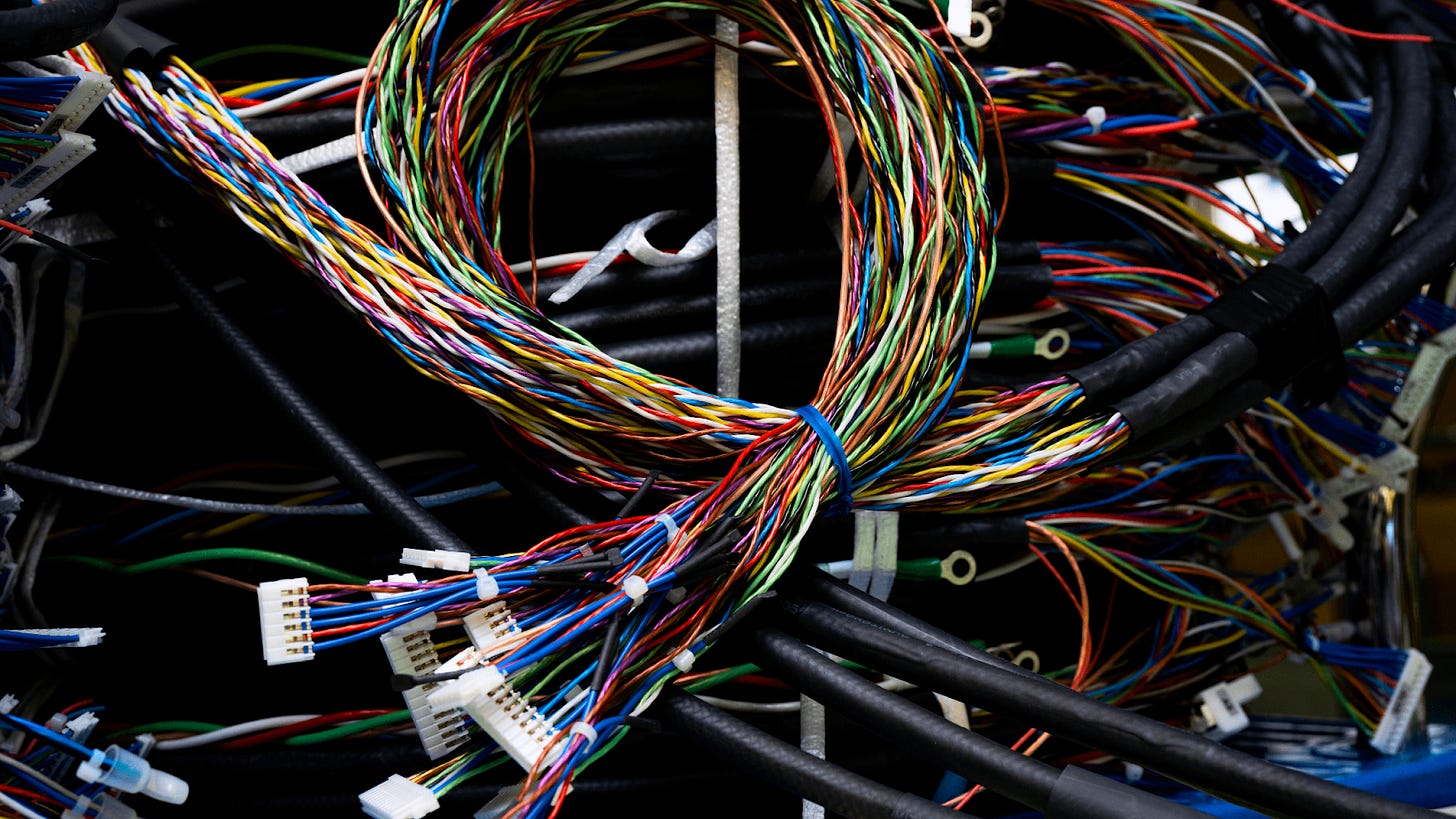

In today’s LA Hard Tech Spotlight, we cover Senra Systems, an advanced manufacturing startup aiming to modernize the production of wire harnesses. These customized bundles of electrical cables and components are one of the core building blocks of every machine in the world. To the uninitiated, Senra might be serving the largest market you’ve never heard of.

Introducing Senra Systems

CEO & Key People: Jordan Black, Ben Shanahan

Founded: 2023

Torrance, CA

Manufacturer of wire harnesses, enabling convenient, transparent, and rapid delivery.

Senra Systems is building the world’s first software-defined wire harness factory. Combining their experiences making custom wire harnesses and developing manufacturing software for SpaceX, founders Jordan Black and Ben Shanahan are working with some of the world's most innovative hardware companies. They bring the rapid iteration and scale orientation that have become legendary elements of SpaceX’s culture to a decaying, yet critical part of the hard tech value chain.

What is a wire harness?

Wire harnesses, aka cable harnesses or wiring assemblies, are highly customized bundles of electrical cables bound together with connectors, terminals, and other components. They are designed to form single, organized, and manageable units that connect the various electrical components, sensors, and devices within a hardware system.

Buried behind polished metal and plastic surfaces, wire harnesses are generally invisible to us as we go about our daily lives. But once you know they exist, you realize that they’re everywhere. Every car, truck, boat, aircraft, microwave oven, espresso machine, television, industrial robot, and rocket engine functions because these complex, custom cables safely and reliably conduct electricity throughout their systems. No wonder wire harnesses make up a $105 billion global market!

Of course, not all wire harnesses are created equal. Your toaster oven and frame TV don’t experience the same environmental conditions as your car. The stakes are also lower if the harnesses fail. But in some cases, wire harnesses are the key failure point that can cause tens or even hundreds of millions in damages.

Faulty aerospace wire harnesses have been the cause of several high-profile mission failures. The Apollo 13 accident was infamously triggered by an oxygen tank igniting a damaged wire insulation. In 2022, a startup’s rocket launch failed to deliver its payload to orbit when a wiring error in the rocket’s separation mechanism prevented stage separation.

Despite their importance, the supply base for this technology is plagued with problems. The supply chain is made up of hundreds of mom-and-pop shops that use little to no technology in the design and manufacturing process. Designs are usually hand-drawn, creating lengthy feedback loops for customers to receive quotes from suppliers. Manufacturing is almost entirely manual as harnesses are assembled by hand on paper formboards.

Despite billions spent on harnesses across the aerospace and defense industrial base, a typical aerospace customer can wait 6+ months to receive their order. And the problem is only getting worse—American manufacturing is constrained by skilled labor shortages, and wire harnessing is no exception.

This is where Senra comes in. By building a vertically integrated, software-powered factory they can shrink lead times on premium harnesses from 6 months to 2 weeks (the same time a traditional supplier might take to provide a quote). Building their production line with speed and automation in mind, they’ve replaced industry-standard hand tools with a platform of advanced machines.

The secret sauce is their foundational design software. Their platform allows them to simplify layout, accelerate collaboration with customers, and enable price and lead time transparency. The tool is also linked to procurement and machine configuration. Parts are automatically ordered, production line machines are calibrated, and work instructions are auto-generated for technicians.

It's safe to say that Senra is completely reimagining the wire harness manufacturing process and creating a new standard for this critical piece of the hardware value chain. With the team they’ve assembled and the culture they’re building, it’s easy to see how they’ll play a critical role in the hard tech ecosystem that is evolving in LA and beyond.

Q&A with CEO, Jordan Black

What had to be true so Senra could exist? Why now?

The world is moving towards mass-electrification, while skilled labor for electromechanical manufacturing is diminishing. In order to meet growing wire harness demand, modernization is needed now more than ever as the manufacturing process has not significantly changed since the Cold War.

How will the world change when you succeed?

The future of American manufacturing is defined by configuration, not automation. Moreover, designing hardware properly from an early stage will be less overlooked.

What has been harder than you expected about building Senra?

The small things such as finding factory space and choosing a logo.

What do you know now that you wish you knew when you first started Senra?

I wish I spent more time outlining the vision of the company early on instead of jumping right into manufacturing harnesses the third week we started.

What motivates you to build this company every day?

The people. Both our customers, who are excited to work with us and fix this problem, and our growing team.

Why is LA the right place for you to build your business?

We are enabling a customer-driven supply chain, so people can design and manufacture their parts when they want and how they want. This requires us being in LA to be close to some of our most important customers.

Behind every successful person, there are people who play or have played significant roles in making it happen. Who’s one person who has helped you get to this point? How have they helped?

Jai Malik (GP at Countdown Capital) was our first investor and the person who believed in us the most. He spent many late nights listening to my crazed obsession about solving this problem to being the cheerleader we truly needed. In addition, our close friends and family have always been very supportive in our efforts, and we could not have built this company without them.

Thanks to Jordan for touring us around the factory back in August. The business has grown a lot since then and they have the capital to expand even more. Check out their open jobs here!